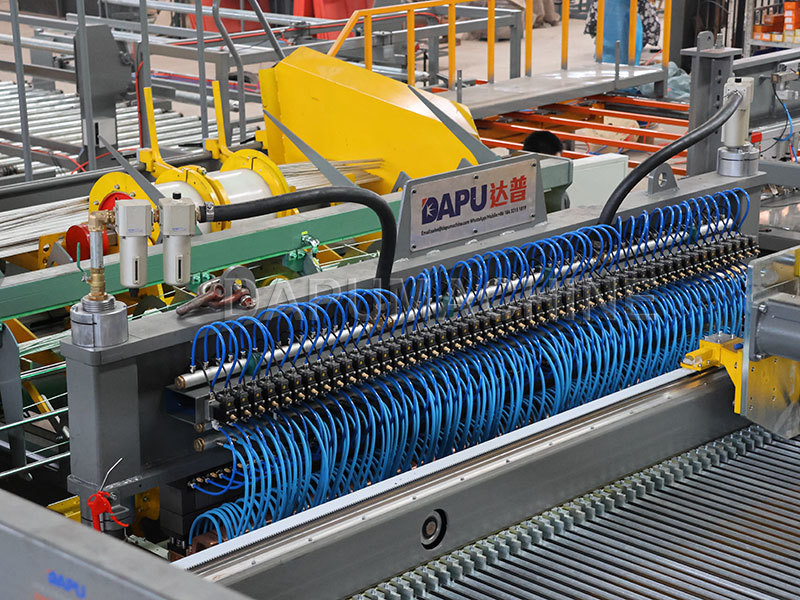

Automatic Wire Feeding: Pre-cut line and cross wires are precisely positioned, reducing labor costs and improving efficiency.

DAPU PRODUCTS

PRODUCTS

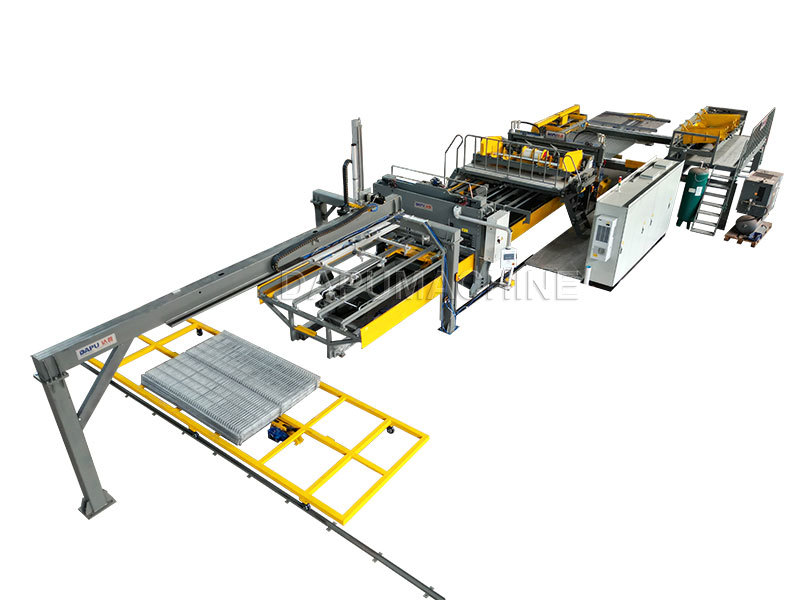

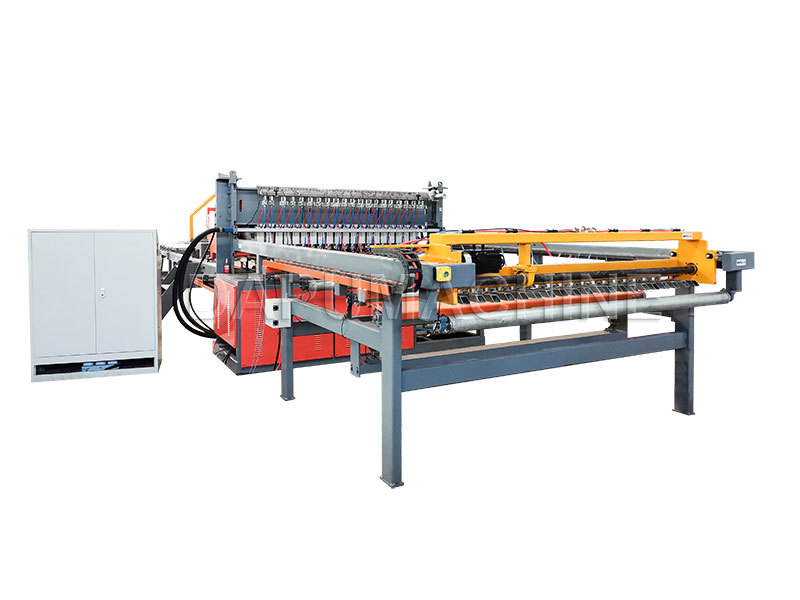

Fully Automatic Fence Mesh Welding Machine

DAPU’s Automatic Fence Mesh Welding Machine ensures fast, precise welding with CNC servo control, ideal for security fencing and construction.

Key words:

Pneumatic Mesh Welding Machine

Automatic Fence Mesh Welding Machine

Classification:

Product Description

| Product Description: |

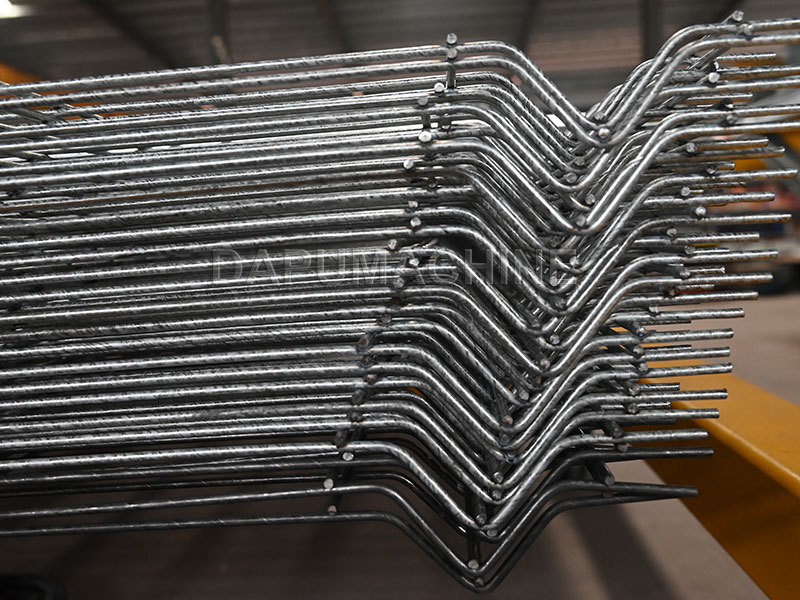

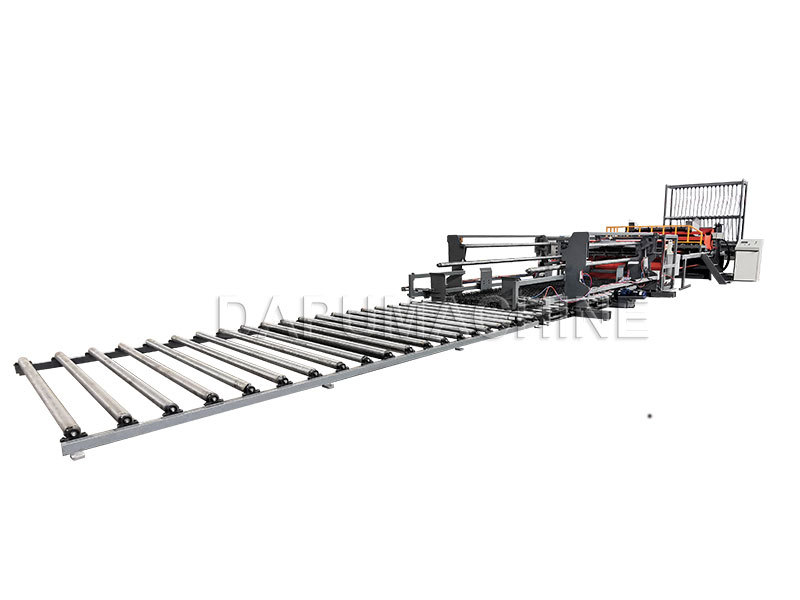

DAPU’s Fully Automatic Fence Mesh Welding Machine is a high-performance solution for producing precise and durable fence panels. Designed with advanced automation and a CNC servo control system, it ensures high efficiency, stability, and accuracy in mesh welding. The machine supports pre-cut line and cross wires, making it ideal for security fencing, construction barriers, and industrial applications.

| Technical Parameters: |

Width of mesh | Max 3000mm |

Length of mesh | 2000mm |

Line wire diameter | 3-6 mm |

Cross wire diameter | 3-6 mm |

Line wire spacing | 50mm |

Cross wire spacing | 50-200mm |

Number of welding electrodes | 61 |

Welding speed | Max 80 strokes/min |

Welding transformer | 125KVA x 16 |

Line wire feeding | Pre-cut |

Cross wire feeding | Pre-cut |

Pressure system | Pneumatic system |

Line wire spacing adjustment | Automatically |

| Machine advantages: |

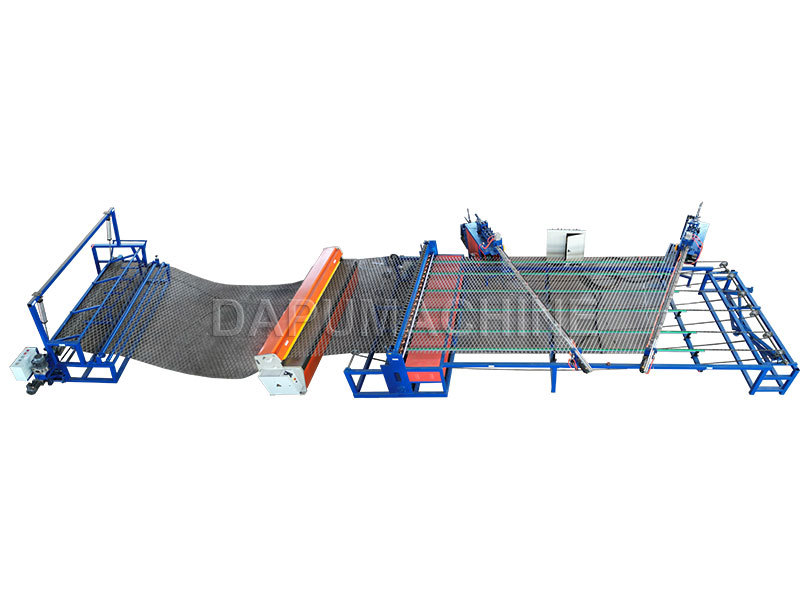

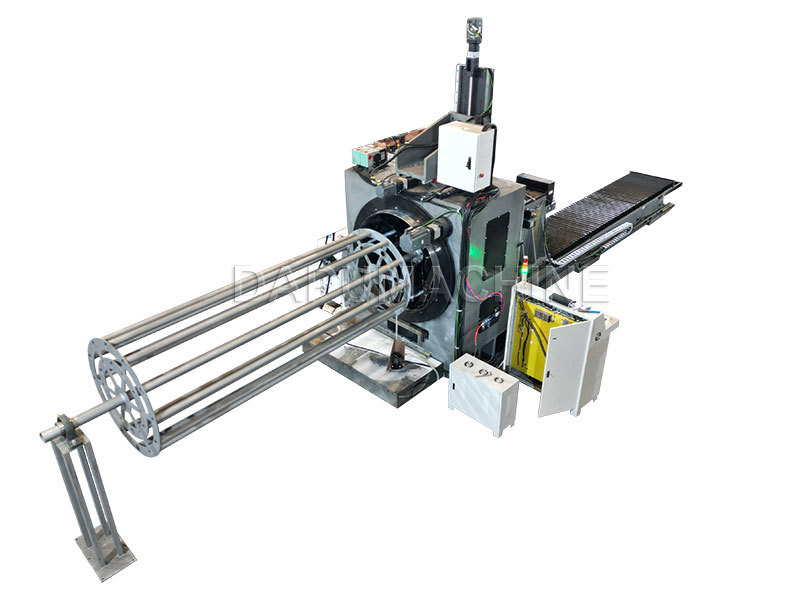

| Auxiliary Equipment: |

| Products and Applications: |

Widely used in construction mesh and breeding mesh, etc.

| Video: |

Click to view the product video

After-sell service including: |

Installation & Commissioning Our engineers can visit your factory for installation and training. Full operation manuals and video tutorials are provided. Technical Support 24/7 online assistance for troubleshooting and technical inquiries. Remote guidance for software or electrical adjustments. | Spare Parts Supply Free spare parts box included with the machine. Additional spare parts available for quick dispatch if needed. Warranty 12-month warranty from the date of installation. If a major component fails due to manufacturing defects, we provide free replacement parts. |

Daily Maintenance Guide |

- Lubrication: Regularly lubricate moving parts, such as the mesh pulling system and welding electrodes, to reduce wear.

- Cooling System Check: Ensure the water cooling system for the welding transformers and electrodes is functioning properly.

- Wire Feeding Inspection: Verify that the pre-cut wire feeding system operates smoothly to prevent misalignment.

- Cleaning: Remove welding slag and dust daily to maintain smooth operation.

- Electrical System Check: Inspect PLC, sensors, and connections monthly to avoid operational issues.

FAQ: |

What wire diameters does the machine support?

The machine supports 3-6mm wire diameters for both line and cross wires.

What is the production speed?

The machine can reach a maximum welding speed of 80 strokes per minute, ensuring high efficiency.

How is the wire fed into the machine?

The line and cross wires are pre-cut and automatically fed for precise placement and welding.

What materials are suitable for this machine?

The machine is compatible with galvanized wire, low-carbon steel wire, and stainless steel wire.

Does the machine support different mesh sizes?

Yes, line wire spacing is adjustable automatically, and cross wire spacing ranges from 50-200mm, allowing customization.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.