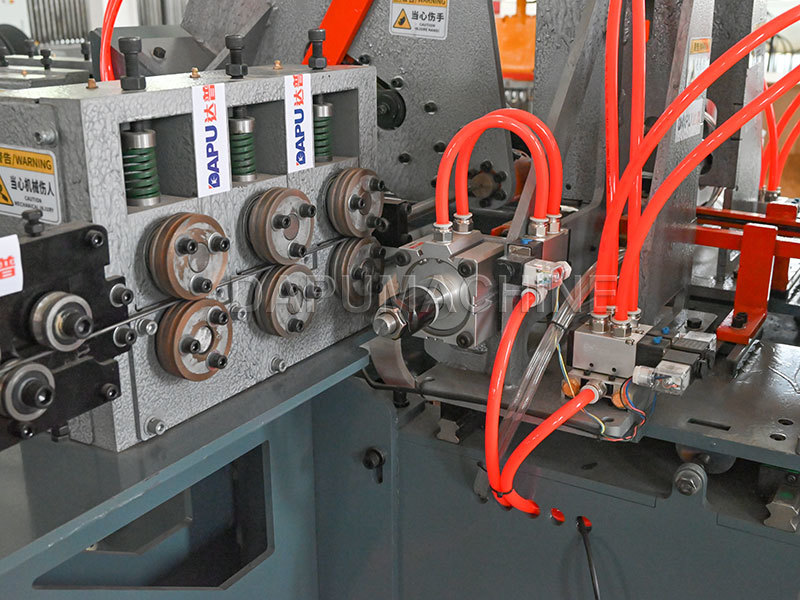

High Automation – Controlled by a Mitsubishi PLC system with a touch-screen interface for easy operation and precise adjustment.

DAPU PRODUCTS

PRODUCTS

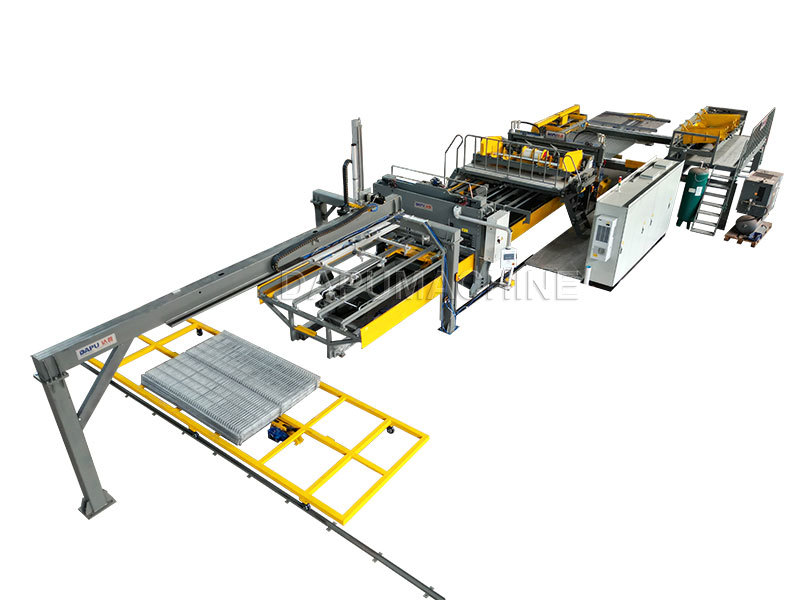

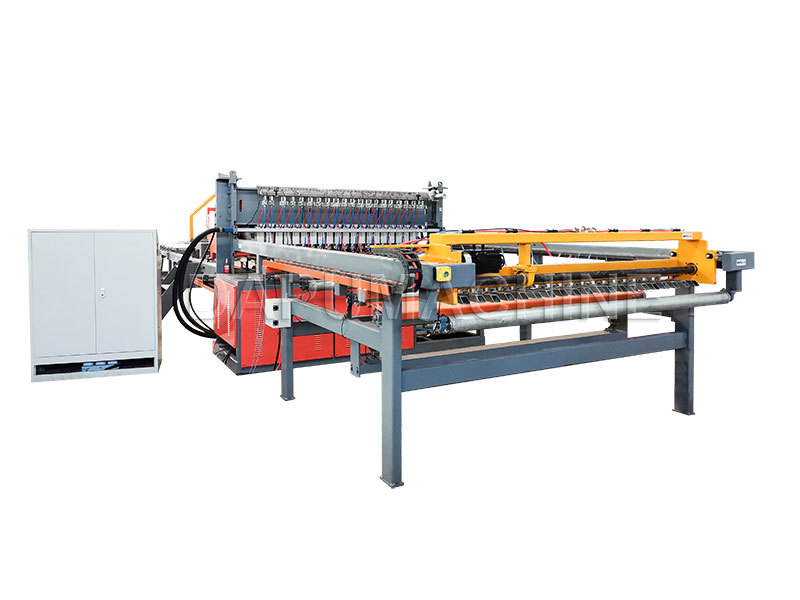

Brick Force Mesh Welding Machine-Sheet type

Automatic brick reinforcement mesh welding machine for 2–5mm wire. High efficiency, stable performance, and durable design for masonry reinforcement.

Key words:

Brick Force Mesh Welding Machine

Brick Force Making Machine

Classification:

Product Description

| Product Description: |

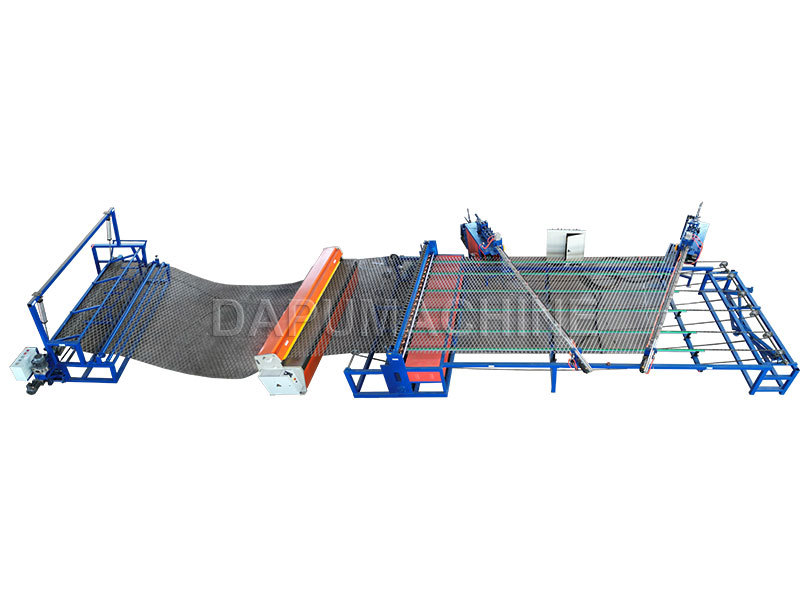

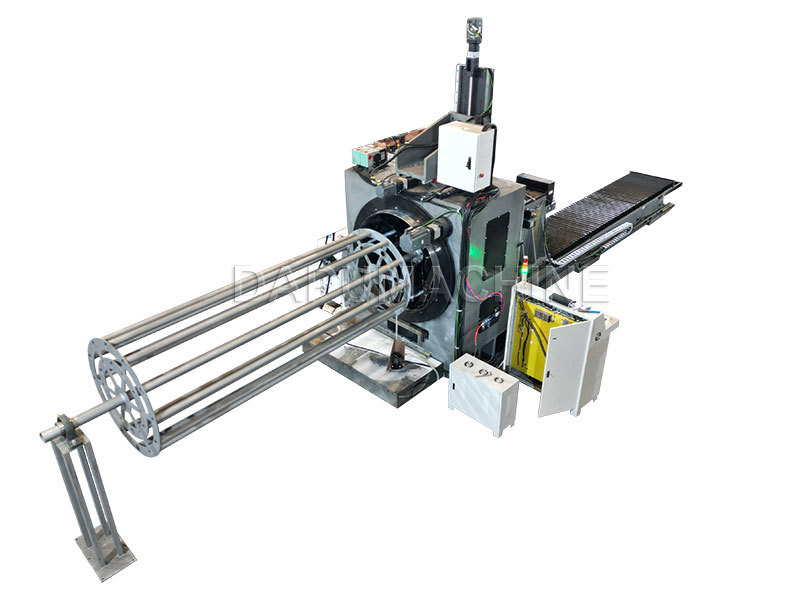

Our fully automated Wedge Wire Screen Welding Production Line represents the ultimate solution for high-volume, precision manufacturing of wedge wire screens. This integrated system combines advanced technology with robust engineering to deliver unparalleled production efficiency and product quality.

| Technical Parameters: |

| Parameter name | Unit | Value |

| Wire diameter | mm | Ф2-Ф5 |

| Max. mesh width | mm | 200 |

| Longitude wire space | mm | 50—200 |

| Cross wire space | mm | 200--400 |

| Number of welding points | point | 2 |

| Welding frequency | one minute | 30--60 |

| Maximum welding capacity | mm | ¢2--¢15 |

| Welding transformer capacity | KVA | 160KVA×2 sets |

| Main transformer capacity | KVA | 250 |

| Welding transformer duty cycle | — | 30% |

| Power supply voltage | V | 380 |

| Current frequency | Hz | 50 |

| Cross wire feeding way | — | Automatic |

| Mainframe dimensions (L×W×H) | m | 18M*7M*3M |

| Total equipment weight | T | 5 |

| Welding transformer | 160KVA | Casting water-cooled transformer |

| Machine advantages: |

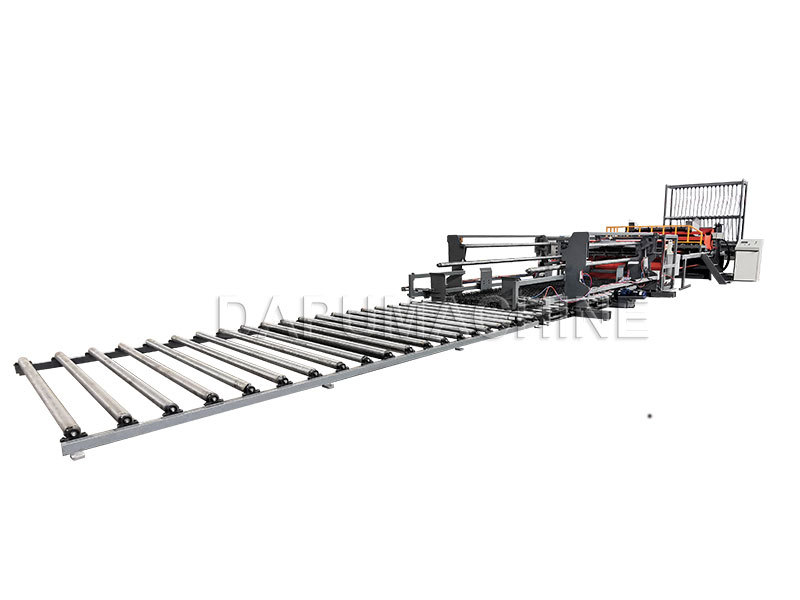

Auxiliary Equipment: |

| Products and Applications: |

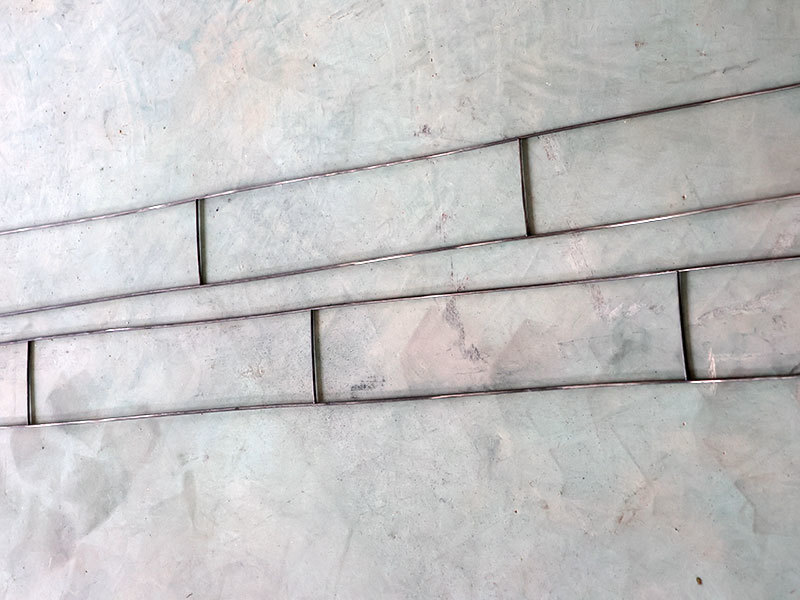

The Brick Force Mesh Welding Machine produces brick force mesh (ladder mesh) commonly used in:

Brick and block wall reinforcement

Masonry construction strengthening

Crack control in concrete walls

Structural support in industrial and residential buildings

Its output meshes are widely applied in construction and infrastructure projects, helping enhance wall stability and prevent cracking.

| Video: |

Click to view the product video

After-sell service including: |

1.Full set installation video from A to Z, 2.Lay-out of the product line and Electric drawing. 3.Installation instruction and Manual. 24HOUR on line service for every question. | Or technician go aboard to installation Cost: 1.Round trip air ticket 2. Visa cost 3.Salary 150USD/day 4.Eating and accommodation |

Packing and Shipping: |

Each machine is carefully packed with plastic film wrapping, anti-static aluminum foil, and non-fumigation wooden cases. It is mounted on iron pallets for safe transport.

FAQ: |

1. What type of wire can the machine weld?

The machine can weld cold-drawn wire and galvanized wire with diameters ranging from 2 mm to 5 mm. Both ribbed and smooth wires are supported.

2. What is the maximum mesh size the machine can produce?

The maximum mesh width is 200 mm, and the mesh length can reach 3000 mm, ideal for brick force (ladder) mesh production.

3. How is the machine controlled?

It uses a Mitsubishi PLC control system with a touch screen interface, making operation easy, intuitive, and precise.

4. What is the welding speed?

The machine can achieve 30–60 welds per minute, ensuring high efficiency and consistent mesh quality.

5. Does the machine require water cooling?

Yes, it is equipped with a forced water-cooling system for the transformer and electrodes, allowing continuous long-term operation.

6. How is the machine packed for shipping?

Each machine is securely packed with plastic film wrapping, anti-static aluminum foil, and non-fumigation wooden cases, mounted on iron pallets for safe export.

7. What after-sales support is available?

We provide installation guidance, commissioning, operator training, and long-term spare parts supply. The machine comes with a one-year warranty under normal use.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.