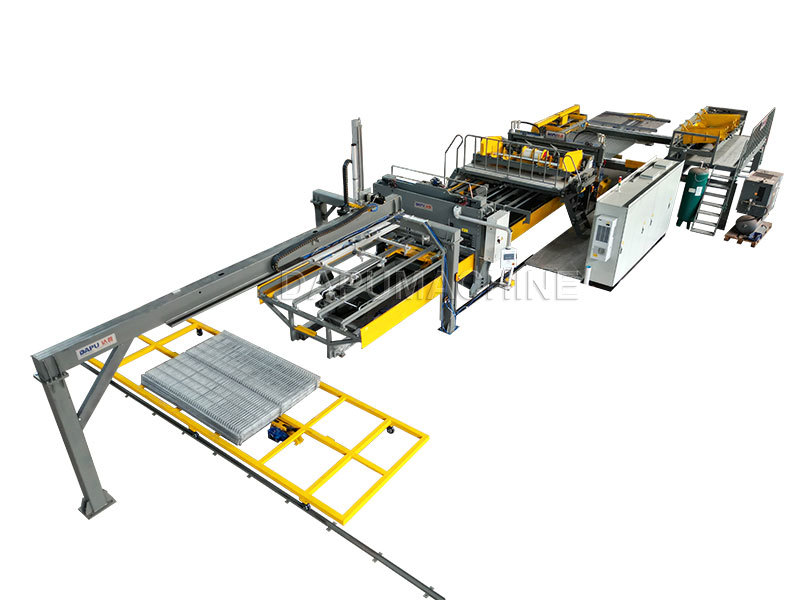

Fully Automatic Operation – Servo-driven wire feeding, automatic cutting, and auto-falling system for continuous mesh production.

DAPU PRODUCTS

PRODUCTS

Brick Force Mesh Welding Machine-Roll Mesh Type

High-speed roll-type brick force mesh welding machine for 1.5–3.2mm wire. Servo-controlled feeding, automatic cutting, and durable performance for masonry reinforcement.

Key words:

Brick Force Mesh

Pneumatic welding mesh machine

Classification:

Product Description

| Product Description: |

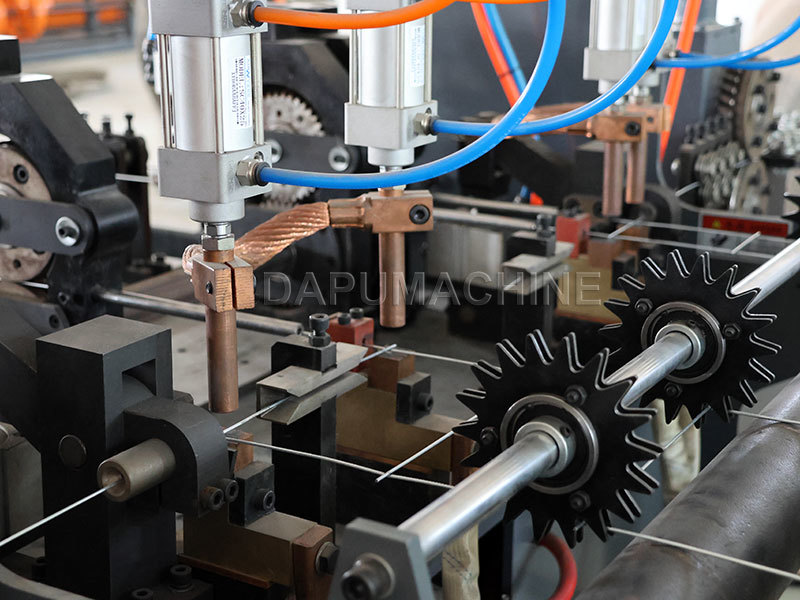

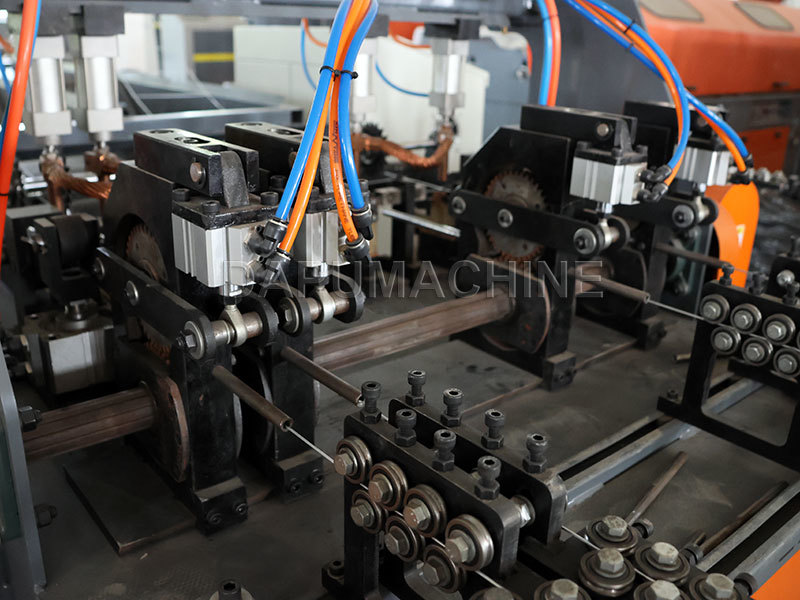

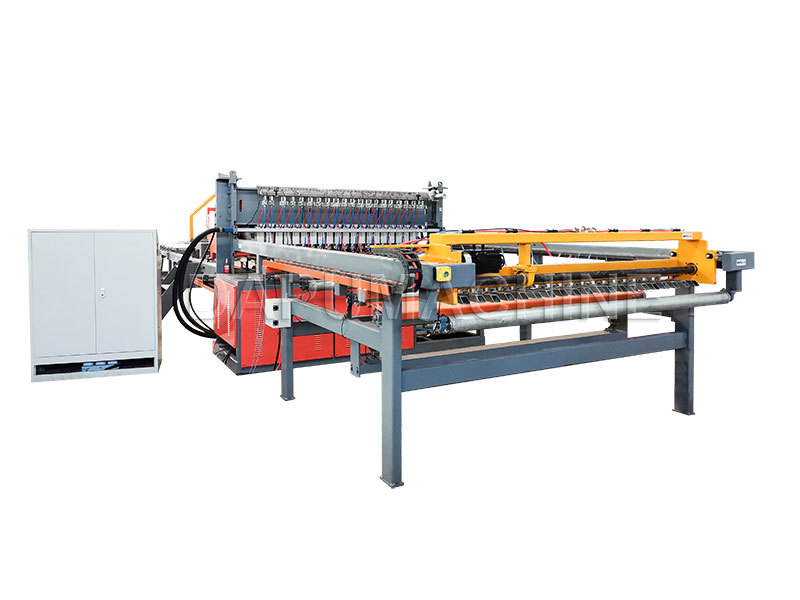

The Brick Force Mesh Welding Machine (Roll Mesh Type) is an advanced automatic system designed for producing continuous brick reinforcement mesh rolls. This model, DP-BF-350, adopts servo motor control for both longitudinal and cross wire feeding, ensuring high precision and efficiency.

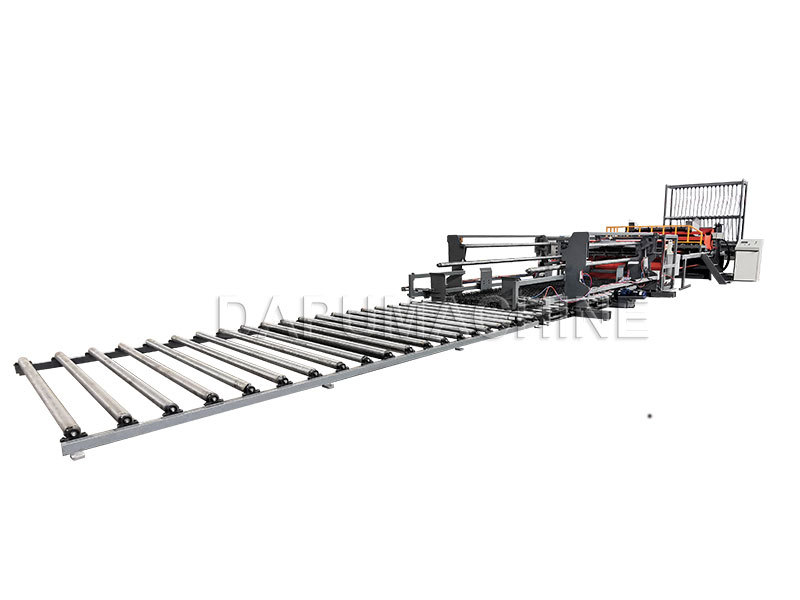

The machine supports 1.5–3.2 mm wire diameter, mesh width up to 350 mm, and mesh length up to 20 meters with automatic cutting and falling functions. It is ideal for producing high-quality brick force mesh for masonry wall reinforcement.

| Technical Parameters: |

Model | DP-BF-350 | |||

Wire diameter | 1.5-3.2mm | |||

Longitude wire space | Min.50 (adjustable) | |||

Cross wire space | 75-350mm (adjustable) | |||

Mesh length | Max.20m (Auto-cutting and Auto-falling) | |||

Welding electrodes | 4 pcs | |||

Welding speed | Max.80-110 times/min | |||

Welding transformers | 85kva (Water cooling transformer) | |||

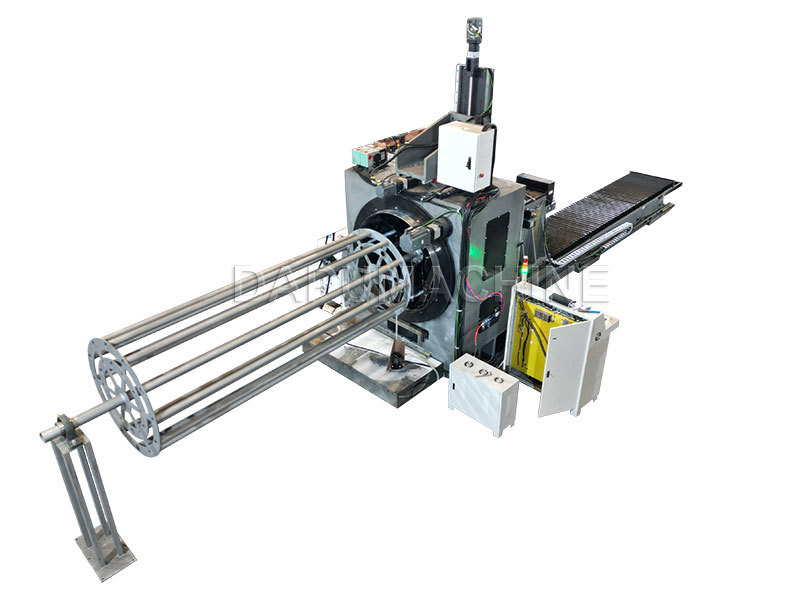

Longitude wire feeding | By Coil | |||

Cross wire feeding | By Coil | |||

Coils | 2 rolls at the same time | |||

| Machine advantages: |

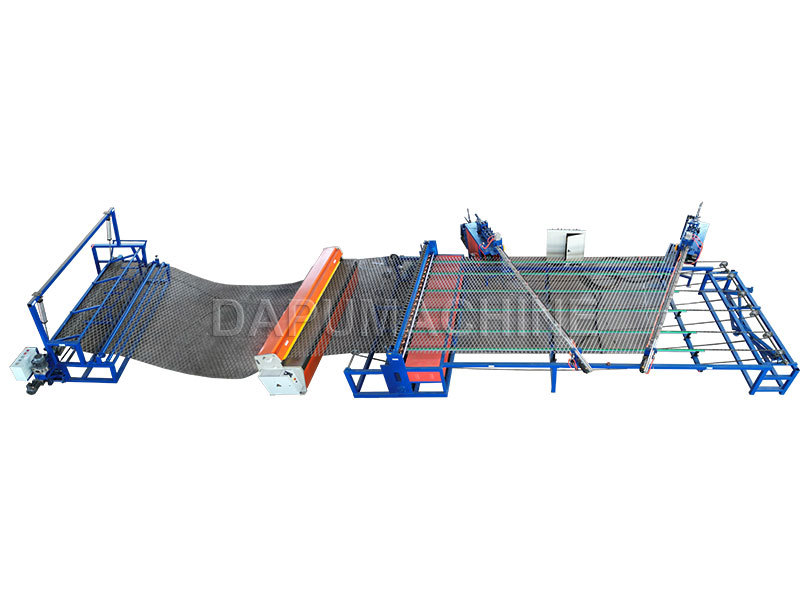

Auxiliary Equipment: |

| Products and Applications: |

This roll-type machine is mainly used for producing brick force mesh (also called ladder mesh or coil mesh) used in:

Reinforcing brick and block masonry walls

Crack resistance in concrete structures

Strengthening construction joints

Industrial and residential wall reinforcement

The continuous roll design improves productivity and simplifies installation on site, making it a preferred solution for large-scale masonry projects.

| Video: |

Click to view the product video

After-sell service including: |

1.Full set installation video from A to Z, 2.Lay-out of the product line and Electric drawing. 3.Installation instruction and Manual. 24HOUR on line service for every question. | Or technician go aboard to installation Cost: 1.Round trip air ticket 2. Visa cost 3.Salary 150USD/day 4.Eating and accommodation |

Packing and Shipping: |

Each machine is securely packed with plastic film wrapping, anti-static aluminum foil, and non-fumigation wooden cases, placed on iron pallets for safe handling.

Estimated delivery time: 60 days after receiving the advance payment, shipping from Xingang Port, China.

DAPU works with reliable logistics partners to ensure safe and timely delivery worldwide.

FAQ: |

1. What wire sizes can this machine weld?

It supports wire diameters from 1.5 mm to 3.2 mm, suitable for both cold-drawn and galvanized wire.

2. What is the maximum welding speed?

The maximum speed reaches 110 welds per minute, ensuring high production efficiency.

3. Can the mesh size be adjusted?

Yes, both line and cross wire spacing (50–350 mm) can be adjusted easily via the touch screen.

4. What’s the difference between roll type and sheet type?

The roll mesh type produces continuous mesh rolls (up to 20 m), while the sheet type makes individual mesh panels.

5. How is the machine installed?

Our engineers can travel to your factory for installation and operator training, or you can use videos, wiring diagrams, and manuals provided by DAPU.

6. What’s the warranty period?

The machine includes a one-year warranty after installation or within 18 months from the B/L date.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.