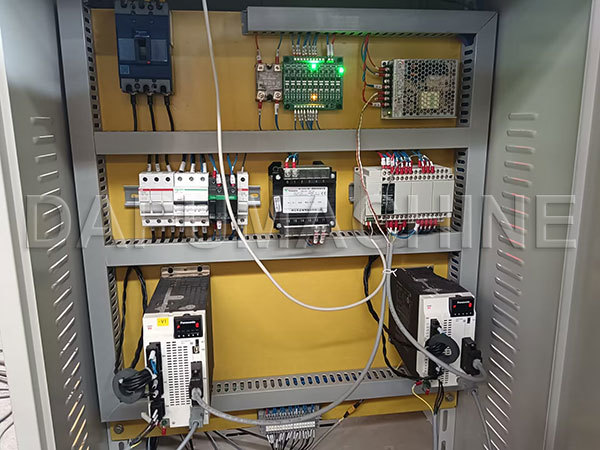

Electrical control cabinet: Panasonic(Japan), Weinview(Taiwan), Schneider(French), ABB (Switzerland) components, all word famous brand, control the machine woking stable.

DAPU PRODUCTS

PRODUCTS

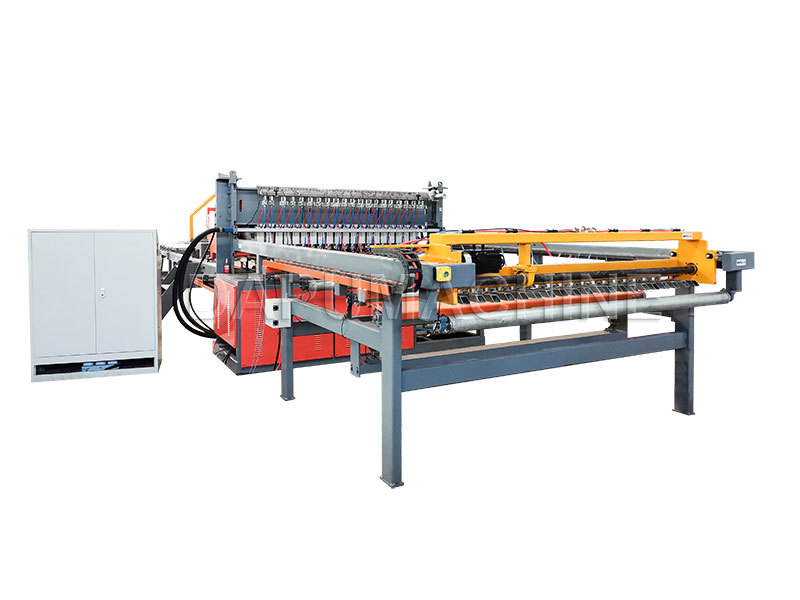

Cable Tray Mesh Welding Machine

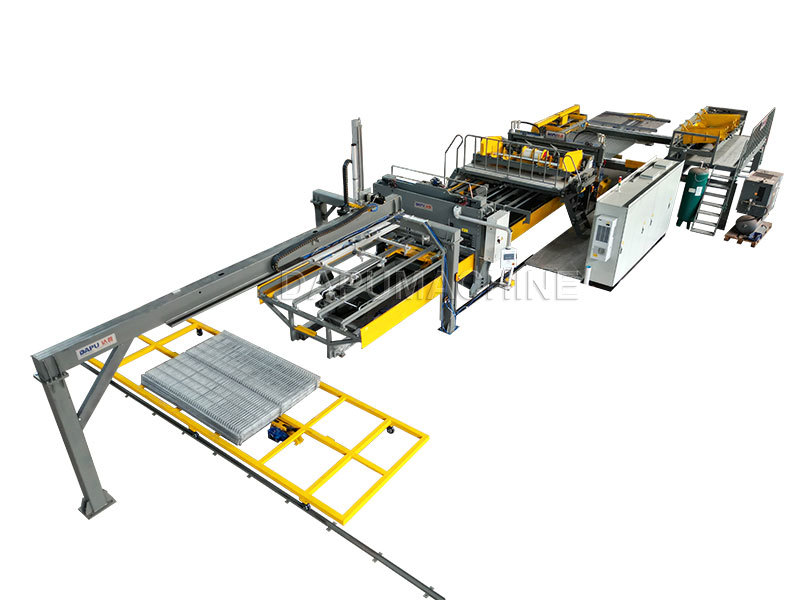

The DAPU cable tray mesh welding machine is a pneumatic - type device, incorporating advanced European design technology. This machine has the remarkable capability to weld two meshes simultaneously, with a maximum working speed reaching 120 times per minute.

Key words:

Pneumatic Mesh Welding Machine

Cable Tray Welding Machine

Classification:

Product Description

| Product Description: |

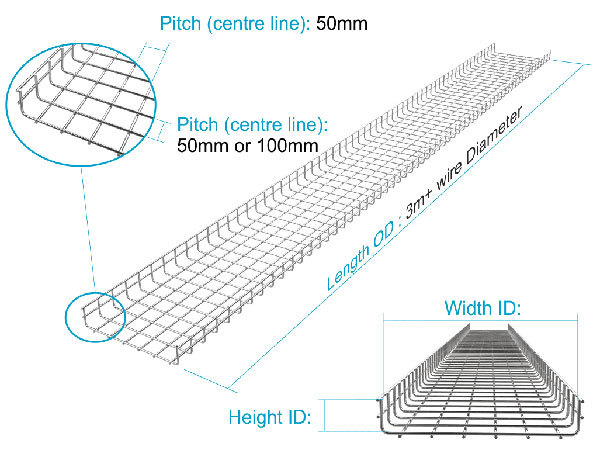

Cable tray mesh welding machine used to cable tray for holding wire cables in factory. Support cables; protect cables; and manage cables. Cable trays use their own structural characteristics to support the attachment and support of cables on buildings (structures), or independently support cables through tunnels or caves, underground, in the air, etc., and are mainly used to support cables.

The machine use latest technology 45 quadra-time force power saving air cylinder. European design. High capacity and good quality mesh, make you competitive in the market.

| Technical Parameters: |

Model | DP-FP-1000A+ (Pneumatic type) |

Wire diameter | 3-6mm |

Line wire space | 50-300mm, Allow four 25mm |

Cross wire space | 12.5-300mm |

Mesh width | Max.1000mm |

Mesh length | Max.3m |

Welding transformer | 150kva*4pcs |

Welding speed | Max.100-120 times/min |

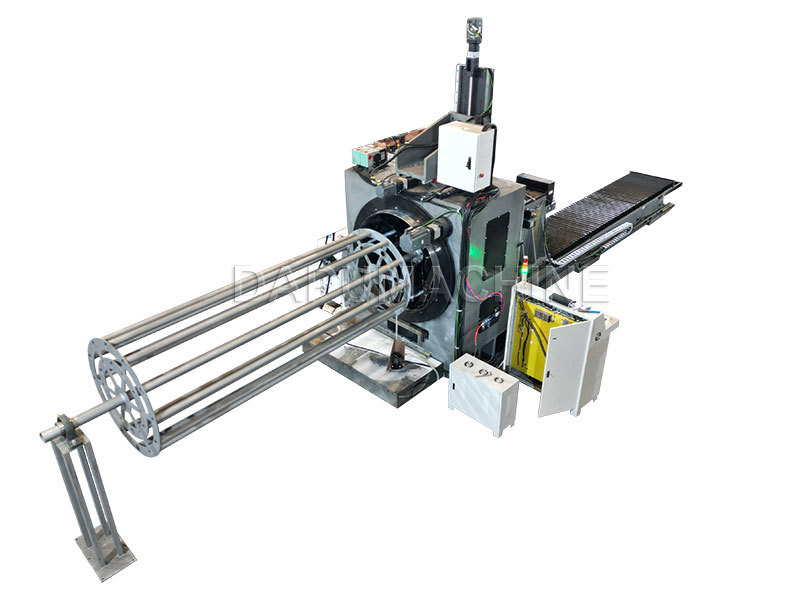

Line wire feeding way | Pre-straighten and pre-cut |

Cross wire feeding way | Pre-straighten and pre-cut |

Machine Weight | 4200KGS |

| Machine advantages: |

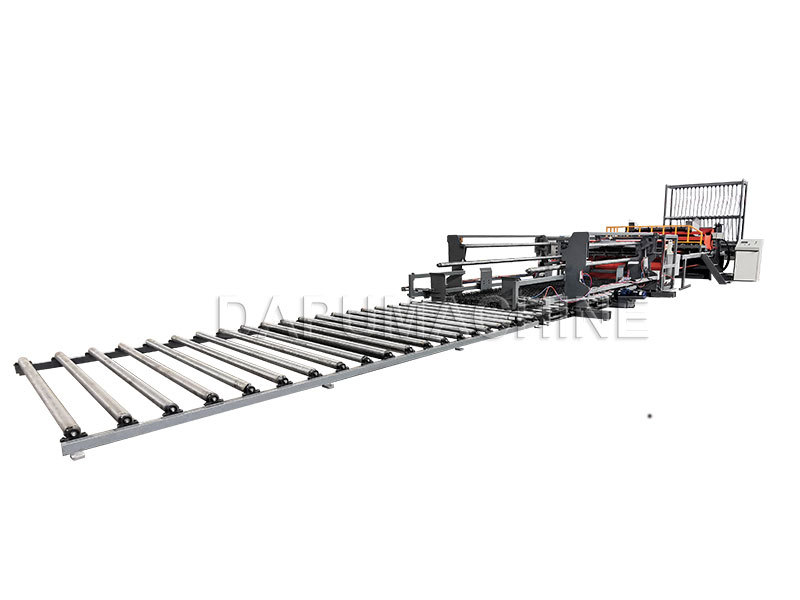

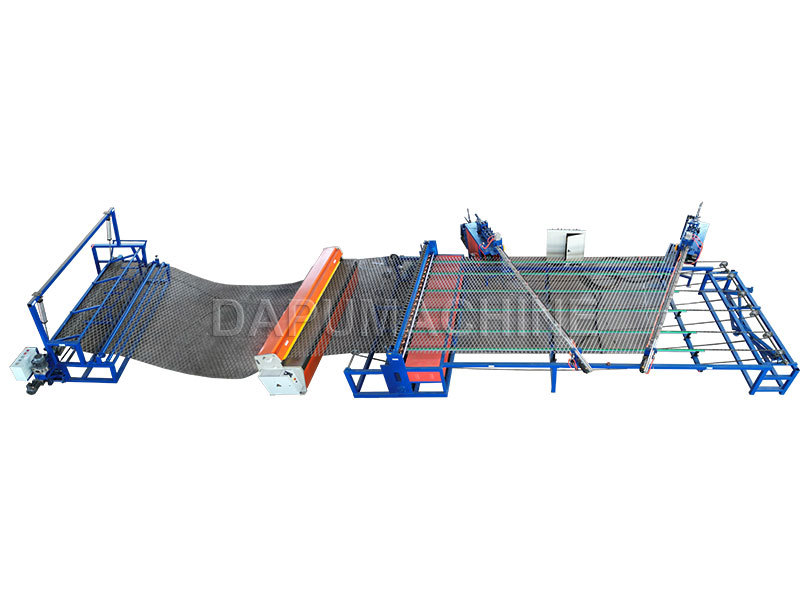

Auxiliary Equipment |

| Products and Applications: |

Products and Applications: Cable tray is used to support and organize cables, wires, and conduits in various types of buildings and industrial facilities. In the recent years, wire mesh cable trays are more popular due to the versatility, ease of installation, and excellent cable management capabilities.

| Video: |

Click to view the product video

After-sell service including: |

1.Full set installation video from A to Z, 2.Lay-out of the product line and Electric drawing. 3.Installation instruction and Manual. 24HOUR on line service for every question. | Or technician go aboard to installation Cost: 1.Round trip air ticket 2. Visa cost 3.Salary 150USD/day 4.Eating and accommodation |

Daily Maintenance Guide |

Lubricate regularly as indication

Checking electric cables connection every month.

Clean the welding situation every day!

FAQ: |

Q: How many container can be loaded in the container?

A: One 40feet container.

Q: How many labor needed to work the machine?

A: 2 workers are enough.

Q: Can you make the machine as our local voltage?

A: Yes, we can make the voltage as your requirements.

Q: Delivery time of the machine?

A: 50 days after receiving the advance payment.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.