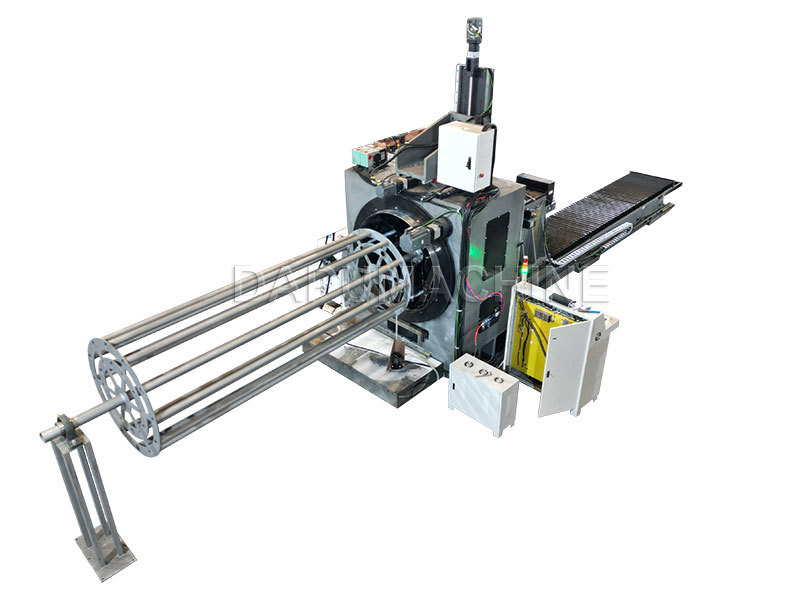

The machine adopts a manual push feeding system for longitudinal wires. After positioning the wires, a single push sends an entire row into the welding unit. This eliminates time-consuming manual inserting, saves labor, and greatly improves loading efficiency.

DAPU PRODUCTS

PRODUCTS

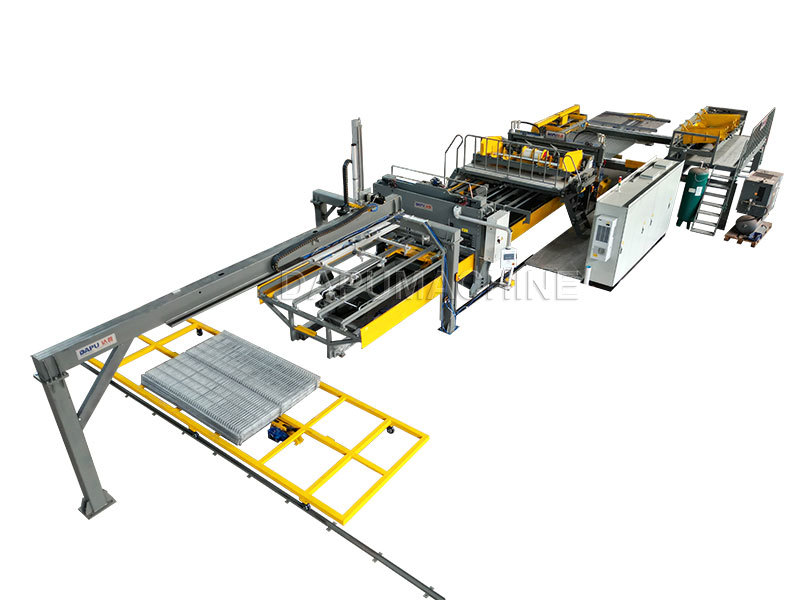

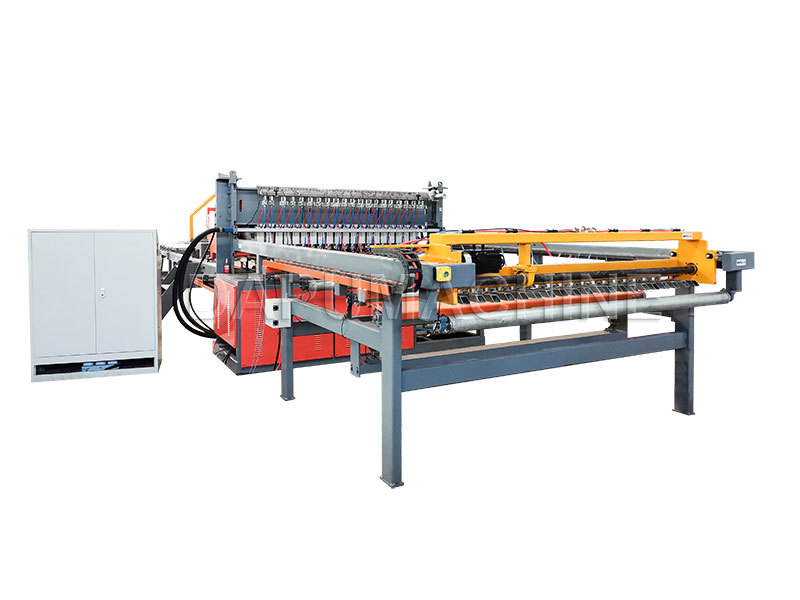

Automatic Fence Mesh Welding Machine 3–6mm

Labor-saving 3–6mm fence mesh welding machine with push-type longitudinal wire feeding. Easy loading, stable welding, and high efficiency for fence production.

Key words:

Classification:

Product Description

| Product Description: |

The 3–6mm Fence Mesh Welding Machine is designed to simplify wire loading and improve production efficiency. Unlike traditional machines that require workers to insert longitudinal wires one by one, this upgraded model uses a manual push-type wire feeding system. After the wires are positioned, the operator only needs to push once to send a full row of longitudinal wires directly into the welding area.

This design significantly reduces labor intensity, shortens loading time, and improves overall production efficiency. Combined with stable welding performance and CNC control, the machine is well suited for fence manufacturers looking for faster and easier daily operation.

| Technical Parameters: |

| Item | Specification |

| Model | DP-FP-2500A |

| Wire diameter | 3–6 mm |

| Line wire spacing | 100–300 mm |

| Cross wire spacing | 50–300 mm |

| Max. mesh width | 2500 mm |

| Max. mesh length | 6000 mm |

| Welding electrodes | 34 pcs |

| Welding transformers | 150 kVA × 6 pcs (separate control) |

| Welding speed | 50–75 times/min |

| Main motor | 5.5 kW |

| Line wire feeding | Pre-straightened & pre-cut |

| Cross wire feeding | Pre-straightened & pre-cut |

| Machine weight | 4.8 T |

| Machine size | 7.0 × 4.0 × 2.3 m |

| Machine advantages: |

Auxiliary Equipment: |

| Item | Specification |

| Model | GT3-6H |

| Control system | Siemens PLC + Siemens touch screen |

| Wire diameter | 3–6 mm |

| Cutting length | 330–6000 mm |

| Cutting error | ±1 mm |

| Working speed | Max. 120 m/min |

| Straightening motor | 7.0 kW |

| Inverter | Inovance |

| Cutting motor | 3.0 kW Inovance servo motor |

| Traction roller | Two groups |

| Straightening die | 7 pcs |

| Wire pay-off capacity | Max. 2000 kg (pneumatic brake) |

| Machine weight | 1600 kg |

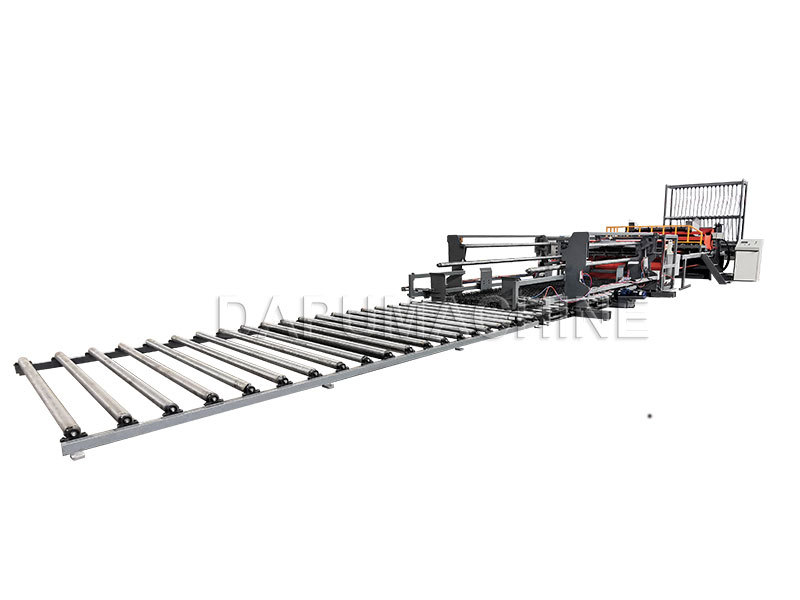

Used to straighten and cut 3–6mm wires with ±1mm cutting accuracy before welding.

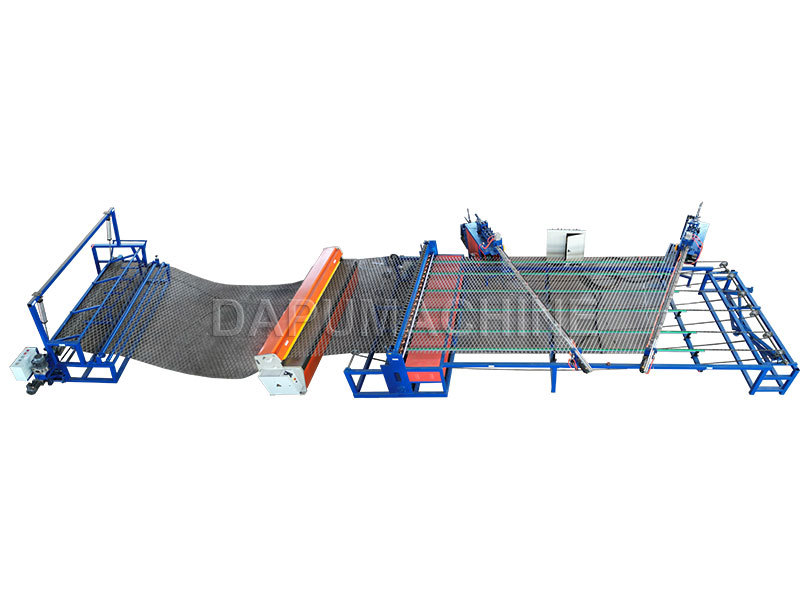

| Products and Applications: |

This machine produces welded fence mesh panels commonly used in perimeter fencing, security fencing, construction sites, factories, roadsides, and agricultural enclosures. The finished mesh panels offer strong welds, consistent spacing, and reliable durability for outdoor and industrial applications.

| Video: |

Click to view the product video

After-sell service including: |

1.Full set installation video from A to Z, 2.Lay-out of the product line and Electric drawing. 3.Installation instruction and Manual. 24HOUR on line service for every question. | Or technician go aboard to installation Cost: 1.Round trip air ticket 2. Visa cost 3.Salary 150USD/day 4.Eating and accommodation |

Packing and Shipping: |

Each machine is carefully packed with plastic film wrapping, anti-static aluminum foil, and non-fumigation wooden cases. It is mounted on iron pallets for safe transport.

FAQ: |

1. What wire diameter can this machine process?

It is designed for steel wires from 3 to 6 mm in diameter.

2. Can the mesh size be customized?

Yes, both line wire spacing and cross wire spacing are adjustable within the specified range.

3. Is the machine suitable for continuous operation?

Yes, the reinforced structure and water-cooled welding system support long-term daily production.

4. What auxiliary equipment is required?

A wire straightening and cutting machine, air compressor, and water chiller are recommended for stable operation.

5. Do you provide installation and training?

Yes, DAPU provides installation guidance, training, and local after-sales service support.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.