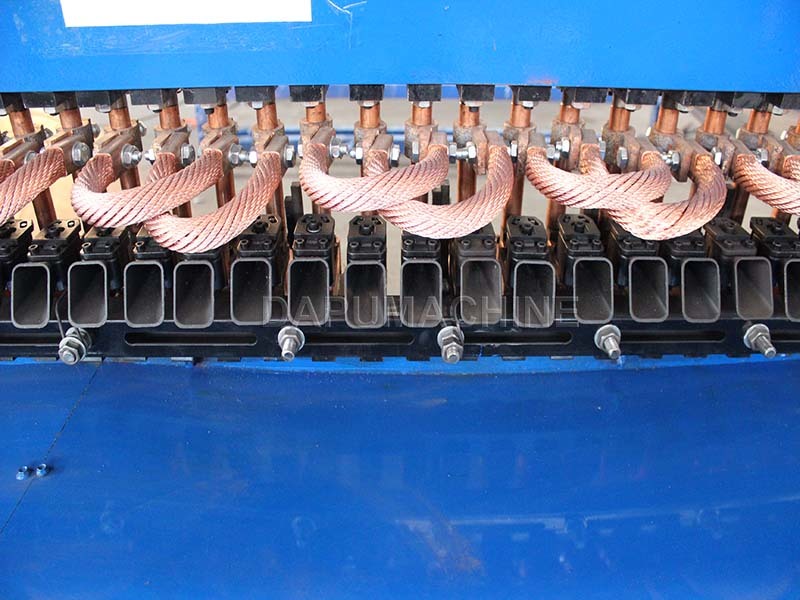

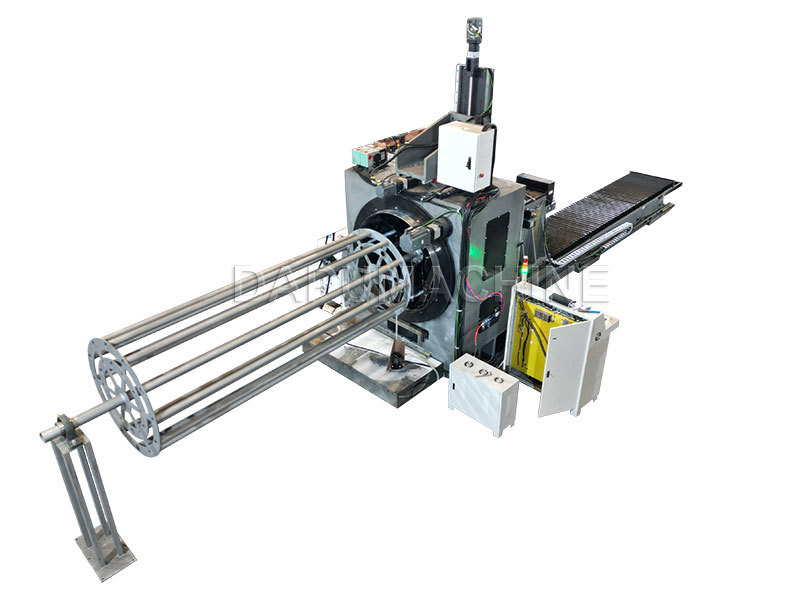

Wire Feeding Slot Tunnel: Ensures smooth and precise wire positioning, reducing misalignment and improving welding accuracy.

DAPU PRODUCTS

PRODUCTS

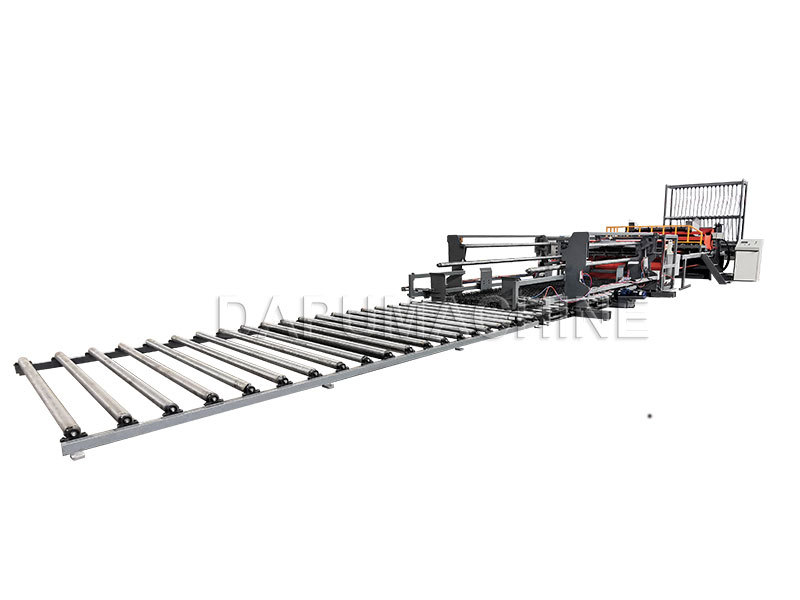

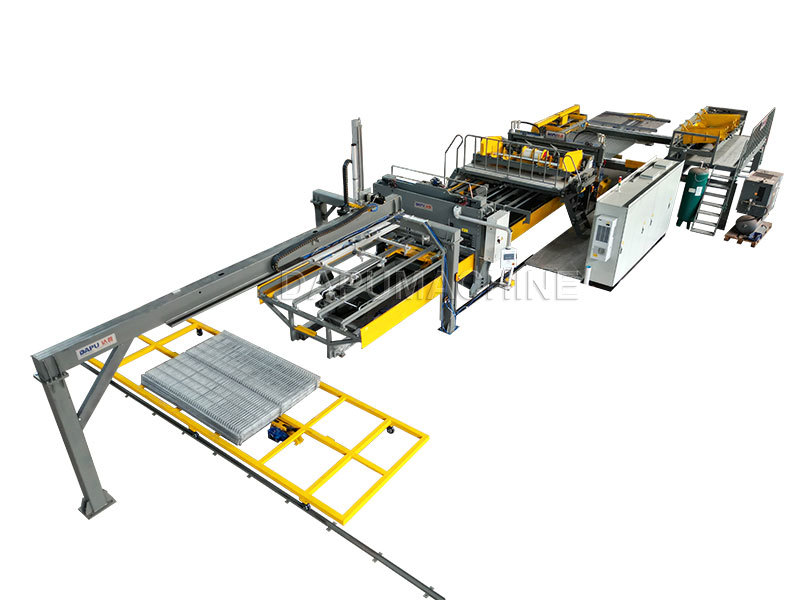

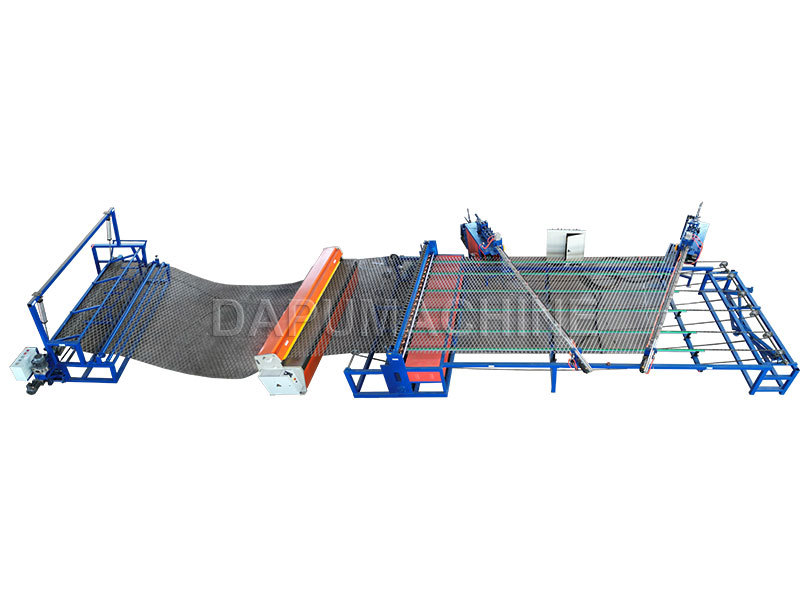

Gabion box welding machine

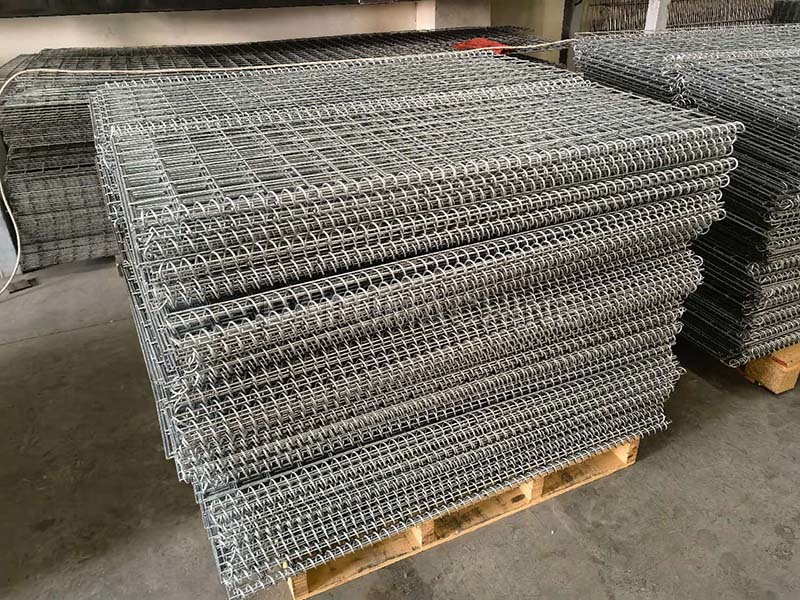

The Gabion Box Welding Machine is designed for efficiently producing welded wire mesh for gabion boxes used in erosion control, retaining walls, and other structural applications. It features high-speed welding, automatic wire feeding, and precise control, ensuring strong, durable, and high-quality mesh suitable for various civil engineering projects.

Key words:

Mechanical Mesh Welding Machine

gabion box welding machine

Classification:

Product Description

| Product Description: |

A Gabion box welding machine is specialized industrial equipment used to manufacture welded gabion boxes, which are wire mesh containers filled with stones or other materials. These boxes are widely used in civil engineering, landscaping, and erosion control projects. Unlike traditional gabion boxes made with woven mesh, welded gabion boxes are constructed using welded wire mesh, providing greater strength and durability.

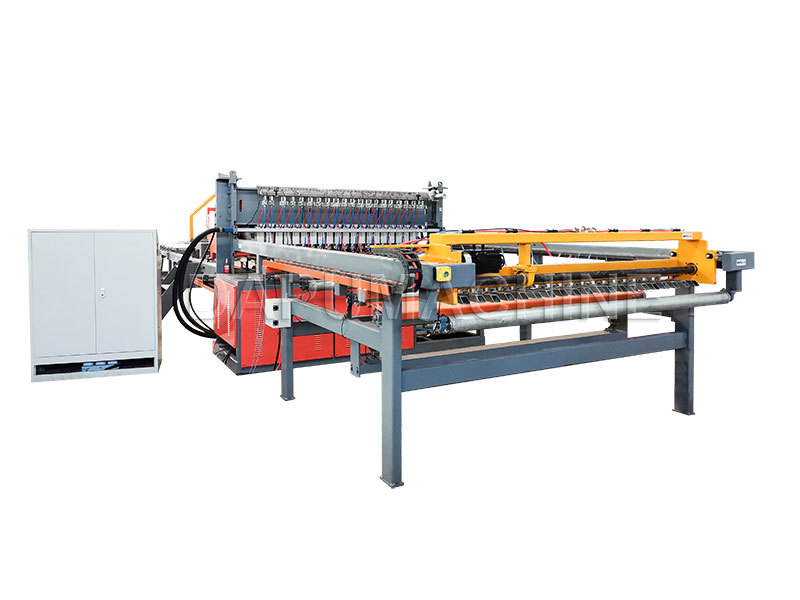

| Technical Parameters: |

Model | DP-FP-2500A |

Wire diameter | 2.5 - 6mm |

Longitude wire space | 2.5 - 4.5mm, Min.50mm |

Cross wire space | Min.12.5mm |

Mesh width/height | Max.2.5m |

Mesh length | Max.6m |

Welding speed | 50 - 75 times/min |

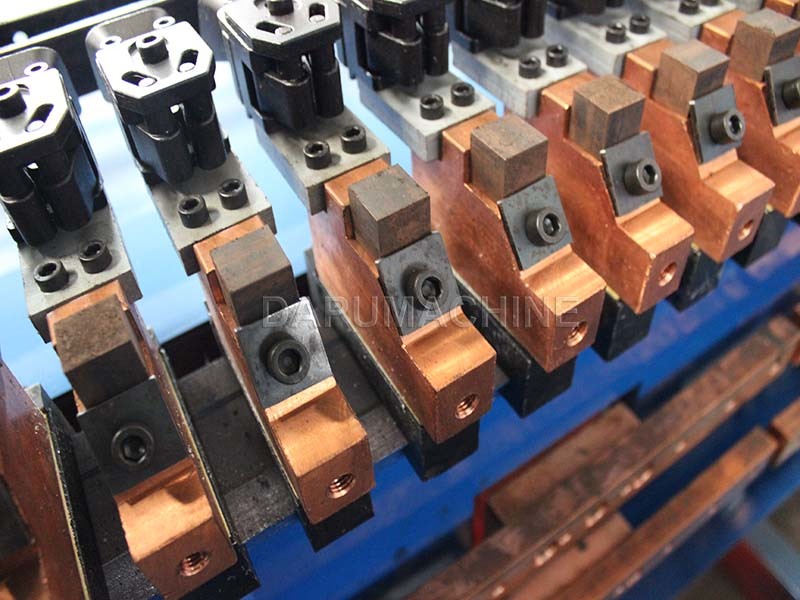

Welding electrodes | 48 pcs |

Welding transformers | 150kva*6pcs |

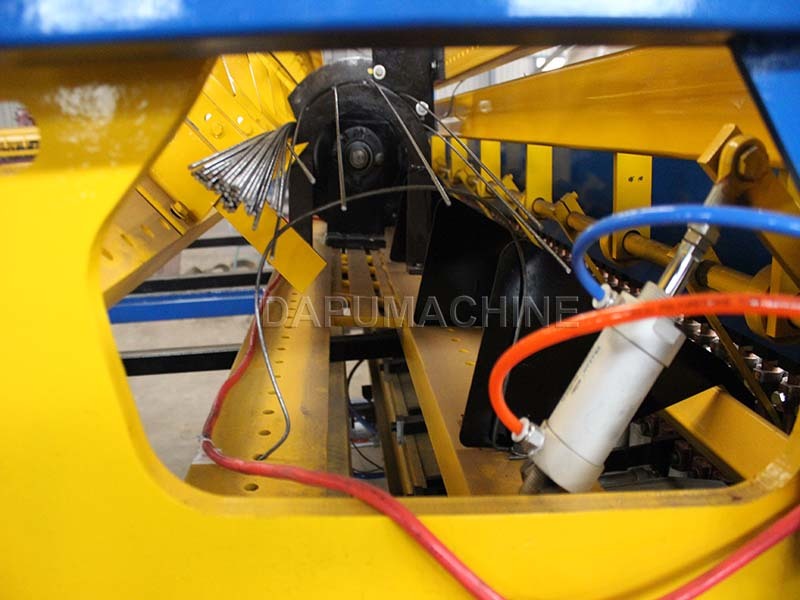

Wire feeding way | Pre-straightened&pre-cut |

Overall Size | 5.0*2*1.7m |

Weight | 3800kg |

Note | Special parameter can be customized; |

| Machine advantages: |

Products and Applications: |

Welded gabion boxes are widely used in various applications, including erosion control to stabilize slopes, riverbanks, and coastal areas. They provide structural support for retaining walls in construction projects and serve decorative purposes in landscaping for gardens, parks, and public spaces. Additionally, gabion boxes act as barriers for flood control, managing water flow during floods, and are essential in infrastructure projects like road construction, bridge abutments, and other civil engineering applications.

|

| Video: |

Click to view the product video

Country we sold to: |

Peru, Brazil, Argentina, Bolivia, Colombia, Mexico, South Africa, Turkmenistan, Saudi Arabia, Malaysia, Thailand, India, Indonesia...and so on.

After-sell service including: |

1.Full set installation video from A to Z, 2.Lay-out of the product line and Electric drawing. 3.Installation instruction and Manual. 24HOUR on line service for every question. | Or technician go aboard to installation Cost: 1.Round trip air ticket 2. Visa cost 3.Salary 150USD/day 4.Eating and accommodation |

After-sell service including: |

Lubricate regularly as indication

Checking electric cables connection every month.

Clean the welding situation every day!

FAQ: |

What are the accepted payment methods?

A: T/T or L/C is acceptable. 30% in advance, we start produce machine. After machine finished, we will send you testing vide or you could come to check machine. If satisfied with machine, arrange balance 70% payment. The we can loading machine to you.

How to transport different type of machine?

A: Normally 1 set of machine need 1x40GP container, decide by the machine type and auxiliary equipment you choose.

The delivery time of mesh welding machine?

A:30-45 days

How to replace worn parts?

A: We have free spare part box loading together with machine. If there is other parts needed, normally we have stock, will send to you in 3 days.

How long is the warranty period of the this machine?

A: 1 year after the machine arrive in your factory. If the main part broken because of quality, not manually mistake operation, we will send you replace part for free.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.