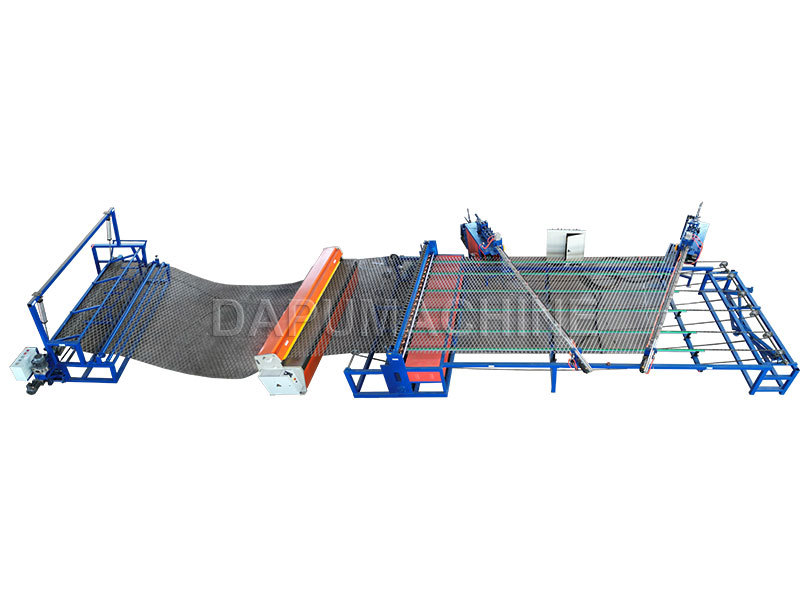

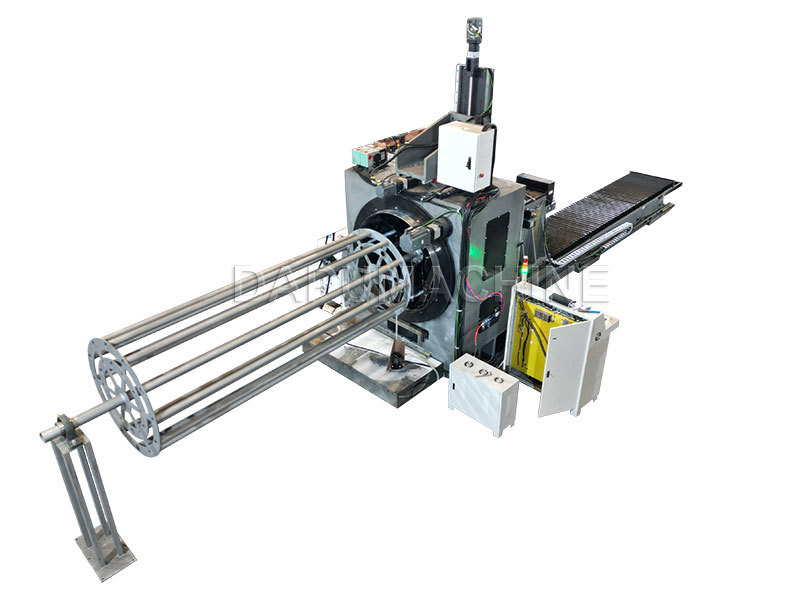

Longitudinal wires are fed directly from wire coils instead of manual insertion.This system supports up to 9mm coil wire, enables continuous feeding, reduces labor demand, and avoids frequent machine stops caused by manual wire placement.

DAPU PRODUCTS

PRODUCTS

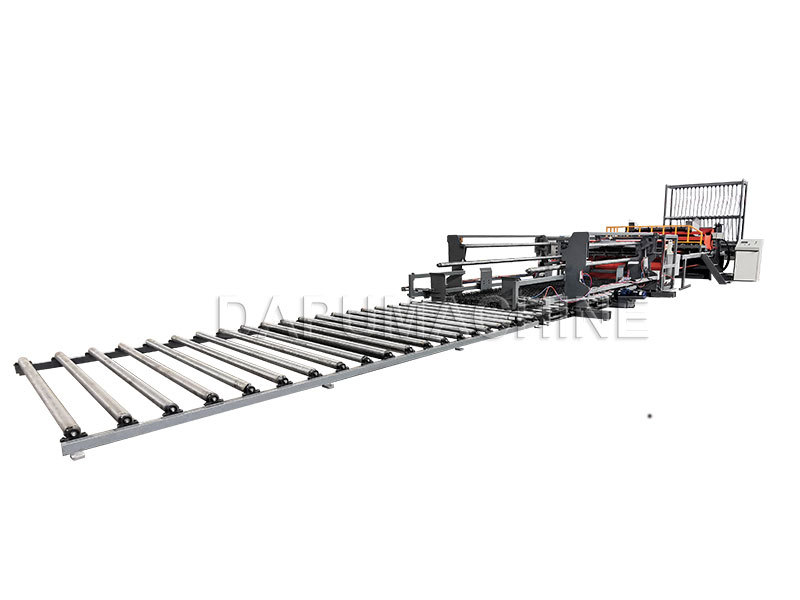

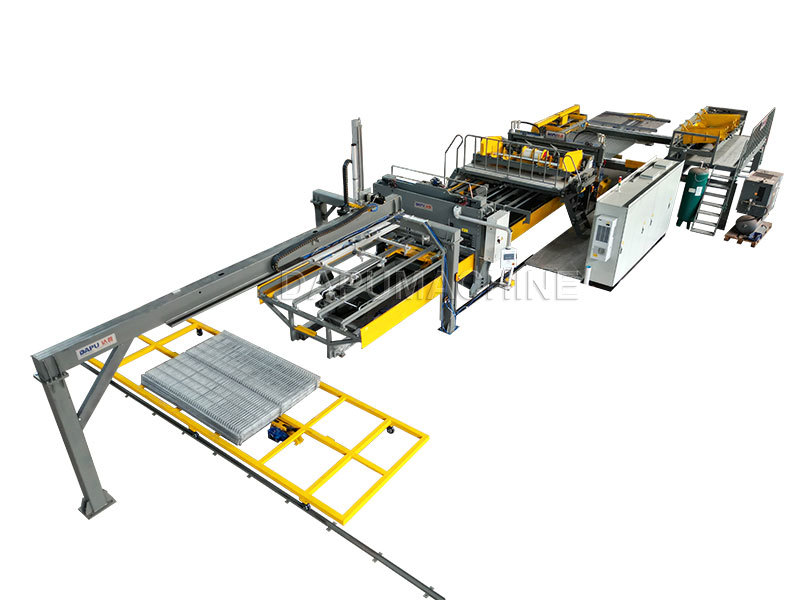

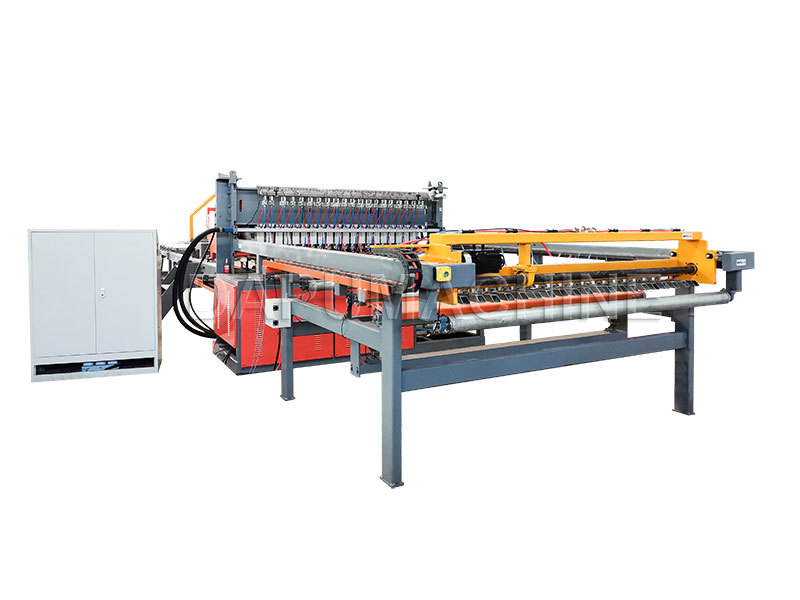

4–9mm Automatic Mesh Welding Machine

4–9mm automatic mesh welding machine with new coil-fed line wire system. Supports pneumatic or mechanical welding, mesh pulling and cutting, and stable panel production for fencing and construction.

Key words:

Classification:

Product Description

| Product Description: |

4–9mm Automatic Mesh Welding Machine is designed for efficient production of welded wire mesh panels with high strength and stable quality.

This model adopts a new-generation automatic line wire feeding system, replacing traditional manual wire insertion. Longitudinal wires are fed directly from wire coils, allowing up to 9mm large-diameter coil wire to be used. This greatly reduces labor requirements and improves production continuity.

The welding main unit supports both pneumatic welding and mechanical welding, giving users flexible choices based on production speed and cost. Combined with a mesh pulling & cutting system, the machine produces flat, accurate mesh panels with consistent dimensions, suitable for fence panels and construction welded mesh.

| Technical Parameters: |

| Item | Specification |

| Model | DP-GW-2000AA+ |

| Wire diameter | 4–9 mm |

| Mesh width | Max. 2000 mm |

| Mesh length | Max. 6000 mm (panel) |

| Longitudinal wire spacing | 100–250 mm |

| Cross wire spacing | Min. 100 mm |

| Welding speed | 40–65 times/min |

| Welding points | 20 points |

| Welding transformers | 150 KVA × 10 pcs |

| Longitudinal wire feeding | Automatic from coil |

| Cross wire feeding | Pre-straightened & pre-cut |

| Machine size | Approx. 14 × 2.4 × 2.5 m |

| Machine weight | Approx. 7 tons |

| Machine advantages: |

Auxiliary Equipment: |

| Products and Applications: |

Finished Products

Welded mesh panels

Fence panels

Construction welded mesh sheets

Applications

Perimeter fencing and security fences

Construction reinforcement mesh

Industrial and infrastructure projects

Although often called a fence mesh welding machine, this model mainly produces flat welded mesh panels, which are widely used across different industries.

| Video: |

Click to view the product video

After-sell service including: |

1.Full set installation video from A to Z, 2.Lay-out of the product line and Electric drawing. 3.Installation instruction and Manual. 24HOUR on line service for every question. | Or technician go aboard to installation Cost: 1.Round trip air ticket 2. Visa cost 3.Salary 150USD/day 4.Eating and accommodation |

Packing and Shipping: |

Each machine is carefully packed with plastic film wrapping, anti-static aluminum foil, and non-fumigation wooden cases. It is mounted on iron pallets for safe transport.

FAQ: |

1. Can the machine use coil wire instead of cut wires?

Yes. Longitudinal wires are fed automatically from coils, up to 9mm diameter.

2. What is the difference between pneumatic and mechanical welding?

Mechanical welding has lower cost and stable performance.

Pneumatic welding offers higher speed and stronger welding points.

3. Is the mesh size adjustable?

Yes. Wire spacing and mesh length can be adjusted through the control system.

4. How many workers are needed?

Usually 3–4 workers are enough for stable production.

5. Can the machine work continuously for long hours?

Yes. With proper cooling and electrical control, it supports long-time continuous operation.

6. Is customization available?

Yes. Voltage, mesh size, and configuration can be customized based on your project.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.