DAPU PRODUCTS

PRODUCTS

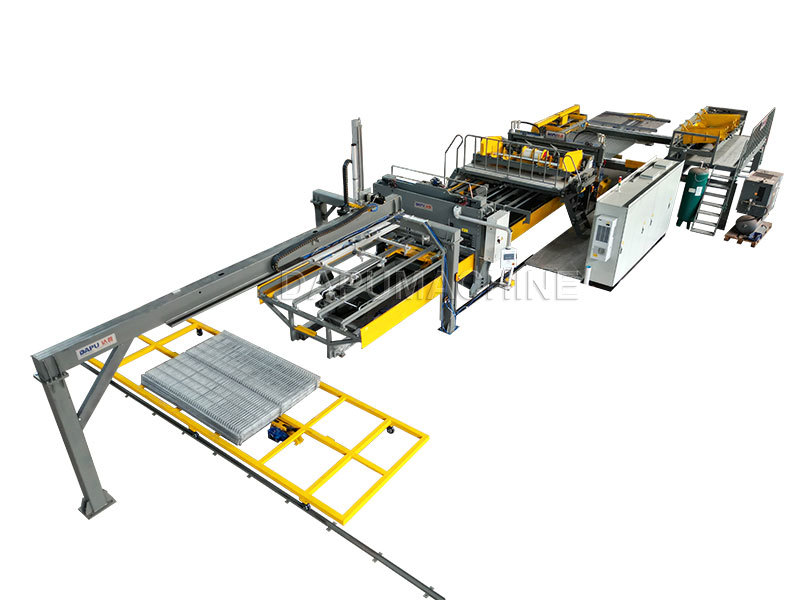

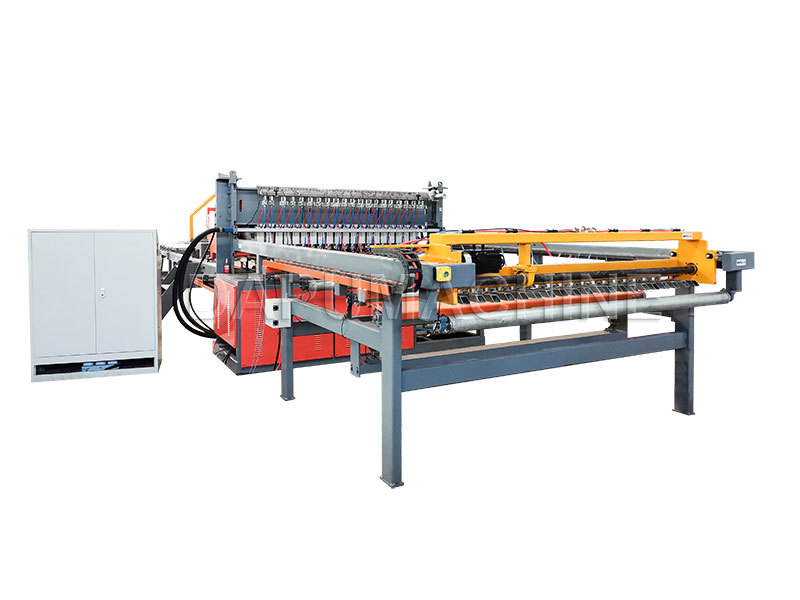

Pneumatic Mesh Welding Machine(DP-PW-1200B)

This machine adopts PLC & HMI Control and it’s full-automatically mesh welding machine. The longitude wire was feeding from coils automatically by air cylinder pushing.

Key words:

Classification:

Product Description

| Description of Mesh Panel Welding Machine: |

This machine adopts PLC & HMI Control and it’s full-automatically mesh welding machine. The longitude wire was feeding from coils automatically by air cylinder pushing. The cross wire should be pre-cut and put pre-cut cross wire into the funnel and the cross wire will fall down one by one from funnel for welding. The feeding distance/cross wire distance is controlled by pneumatic cylinder with each step. So the mesh aperture is very accurate. It’s one full automatic working process from wire coils, feeding, welding to cutting mesh in one time without stop. It’s very easy to operate this machine. And it can be operated by automatically working and separate step working.

| Technical Parameter of Mesh Panel Welding Machine: |

| Wire Diameter | 2.5mm—4.0mm | Longitude Wire Feeding | From Wire Coils |

| Longitude Wire Space | 50mm | Cross Wire Feeding | Pre-cut and straightened |

| Cross Wire Space | 50mm | Rated Electrical Power | 85kvaX3 pcs |

| Width of Mesh | 1200mm | Rated Voltage | 3-phase,380V/220V/415V/440V 50Hz or 60Hz |

| Welding Electrodes | 25pcs | Weight | 3200Kg |

| Welding Speed | 26 times/min. | Overall Size | 1.7MX1.9MX2.1M |

| Auxiliary Equipment: |

|

|

|

|

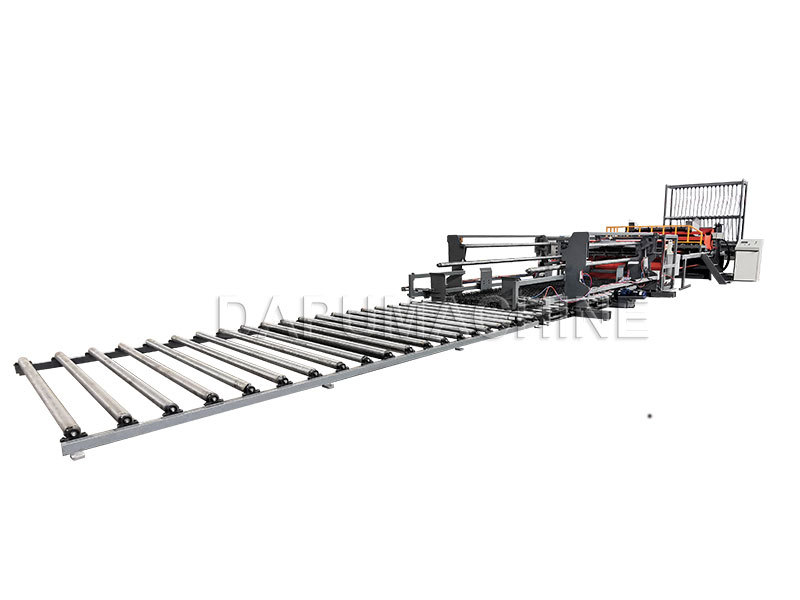

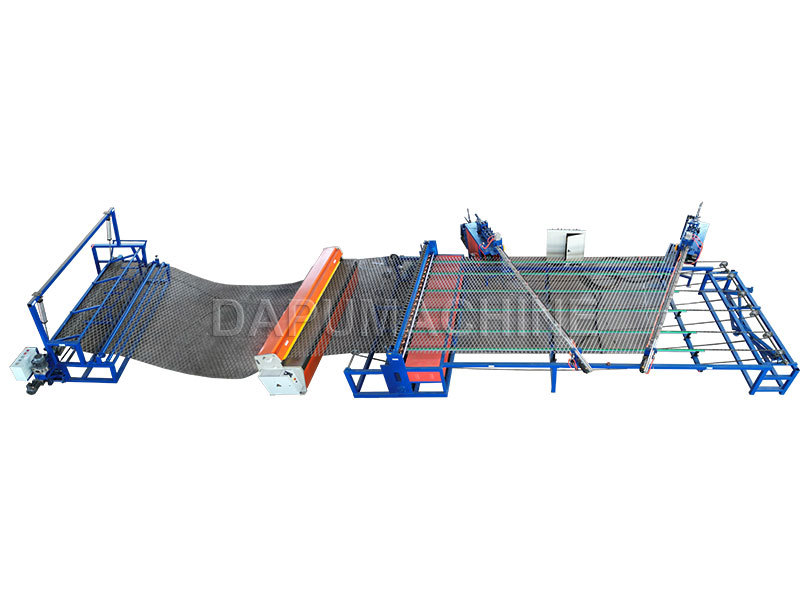

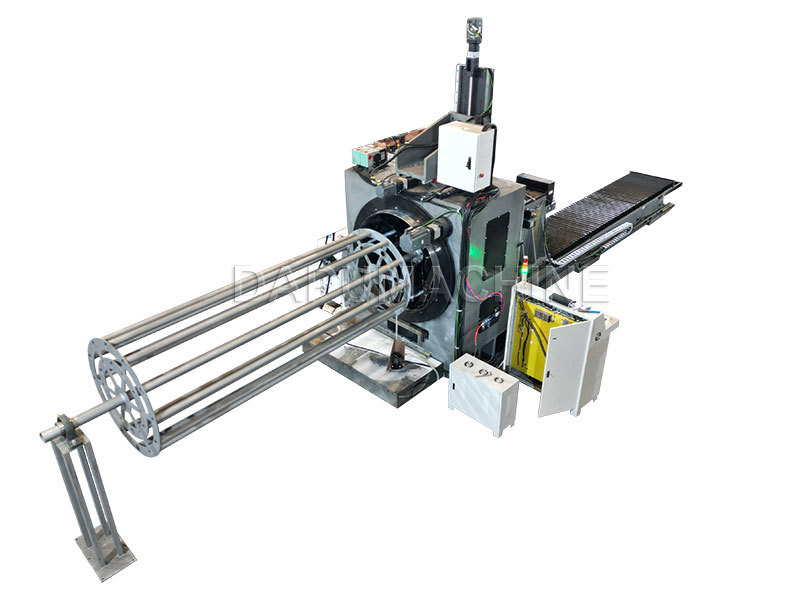

| Mesh Repairing Machine | Wire coils | Wire Rolling Machine | Wire Straightening & Cutting Machine |

| Finished products & Application: |

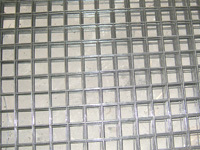

1. Mesh fence, casting roof mesh in the building

2. Construction (3d panel covered mesh, floor warmness preserving mesh, seedbed mesh, floor room mesh, animal cages)

|

|

|

| Video of Mesh Panel Welding Machine: |

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.